For anyone looking to build or understand their CNC machine, the Cnc Shield V3 Pinout Datasheet is an indispensable resource. This document acts as a blueprint, detailing every connection point and its function on the popular CNC Shield v3. Understanding this pinout is crucial for correctly wiring up stepper motor drivers, limit switches, spindle controls, and other essential components, ensuring your CNC project runs smoothly and reliably.

Demystifying the Cnc Shield V3 Pinout Datasheet

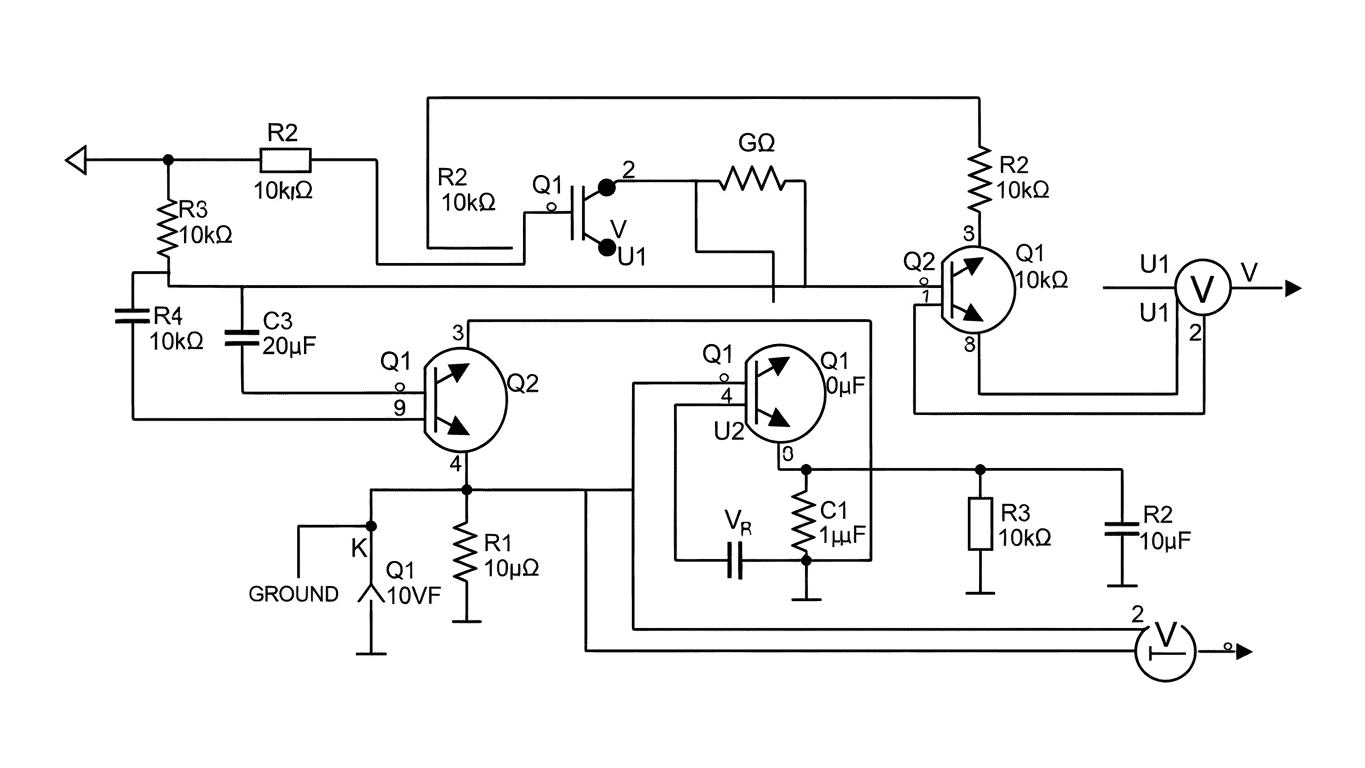

The Cnc Shield v3 is a versatile add-on board for Arduino microcontrollers, specifically designed to control stepper motors for CNC applications. The Cnc Shield V3 Pinout Datasheet provides a comprehensive map of all the pins available on this shield. Think of it as a detailed instruction manual that tells you exactly where to plug in your wires for each specific function. This includes:

- Stepper Motor Drivers: Dedicated sockets and pins for common stepper drivers like the A4988 or DRV8825. These drivers are responsible for translating digital signals from the Arduino into the precise movements of your CNC machine's axes. The pinout clearly labels which pins control step, direction, and enable for each axis (X, Y, Z, and often a fourth, A).

- Limit Switches: Input pins are designated for connecting limit switches. These are safety devices that tell your CNC machine when an axis has reached its physical limit, preventing crashes and damage. The datasheet will show you which pins are used for these crucial inputs.

- Spindle Control: Pins are also available for controlling your spindle motor. This can include PWM (Pulse Width Modulation) pins for variable speed control and digital pins for turning the spindle on and off.

The importance of accurately referencing the Cnc Shield V3 Pinout Datasheet cannot be overstated. Incorrect wiring can lead to damaged components, erratic machine behavior, or a complete failure to operate. By understanding the pinout, you can also identify potential expansion points and troubleshoot issues more effectively. For instance, the datasheet might present the pin assignments in a clear table:

| Function | Arduino Pin | Shield Pin |

|---|---|---|

| X-Axis Step | D8 | STEP (X) |

| X-Axis Direction | D9 | DIR (X) |

| Z-Axis Enable | D12 | EN (Z) |

Beyond the primary motor and switch connections, the Cnc Shield V3 Pinout Datasheet also details pins for features like an emergency stop button, coolant control, and even analog inputs that could be used for various sensors. Each pin is meticulously labeled, often with corresponding Arduino pin numbers, making the connection process logical and organized. For example, you'll find distinct sections for:

- Power inputs (e.g., for motors and logic)

- Stepper driver interface pins

- Digital inputs/outputs

- Analog inputs

This detailed breakdown allows hobbyists and engineers alike to confidently assemble their CNC systems. Whether you're using Grbl, Smoothieware, or another firmware, the pinout remains the fundamental guide for establishing communication between your microcontroller and the physical components of your CNC machine.

To ensure you are correctly wiring your CNC Shield v3 and avoid costly mistakes, please refer to the specific Cnc Shield V3 Pinout Datasheet provided by your shield's manufacturer or commonly available online resources dedicated to this hardware. This document is your essential guide.