In the realm of engineering and product development, the "Datasheet 200f" stands as a critical document, a cornerstone of understanding and implementation. This detailed guide provides essential information about a specific component or system, ensuring that users can work with it effectively and safely. Whether you're a seasoned engineer or a curious hobbyist, grasping the contents of a Datasheet 200f is paramount for successful projects.

Understanding the Core of Datasheet 200f

At its heart, a Datasheet 200f is a comprehensive technical document that outlines the characteristics, performance, and usage guidelines of a particular product. Think of it as a detailed instruction manual and specification sheet rolled into one. It’s where you'll find the nitty-gritty details that govern how a component behaves, its limitations, and how to integrate it into a larger system. The importance of accurately interpreting and applying the information within a Datasheet 200f cannot be overstated ; it prevents costly errors, ensures optimal performance, and guarantees the safety of both the user and the product.

Datasheets typically cover a wide array of information, often presented in a structured and organized manner. Common elements include:

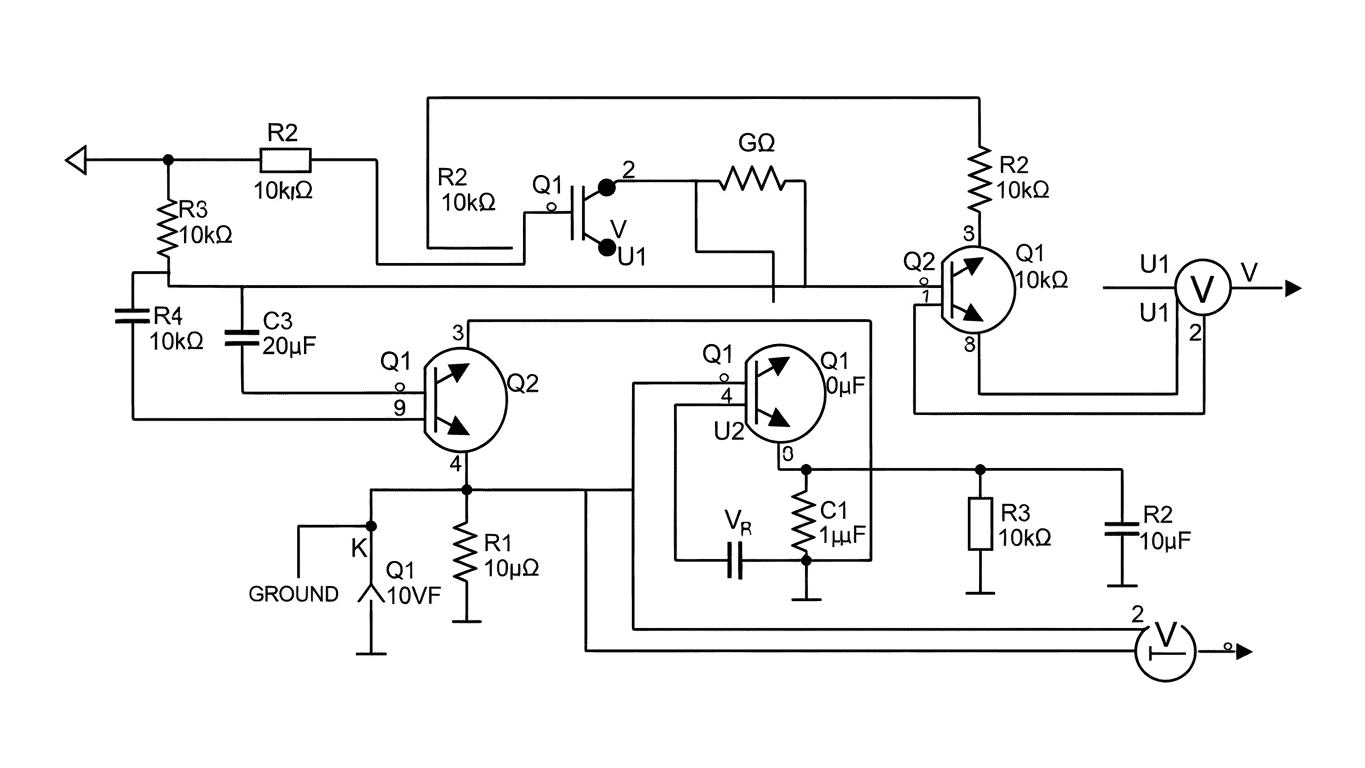

- Electrical characteristics (e.g., voltage, current, resistance)

- Mechanical dimensions and specifications

- Operating temperature ranges

- Performance curves and graphs

- Application notes and recommended usage

- Safety warnings and compliance information

For instance, a Datasheet 200f for an electronic component might present its power consumption, signal timing, and pin configurations. For a mechanical part, it could detail its material strength, tolerances, and assembly procedures. The exact content will, of course, vary depending on the nature of the product, but the underlying purpose remains the same: to provide a complete technical profile.

The utilization of a Datasheet 200f is diverse and spans across various stages of a product's lifecycle. In the design phase, engineers consult datasheets to select appropriate components that meet their system's requirements. During prototyping, the datasheet guides the assembly and testing processes. For manufacturing, it serves as a reference for quality control and production standards. Even for troubleshooting and repair, a Datasheet 200f is an invaluable resource for diagnosing issues and finding solutions. Consider this table as a simplified example of information found within a datasheet:

| Parameter | Value | Units |

|---|---|---|

| Operating Voltage | 5 | VDC |

| Max Current Draw | 250 | mA |

| Operating Temperature | -40 to 85 | °C |

To truly harness the power of technical documentation and ensure you have the most accurate and relevant information for your project, meticulously review the comprehensive details provided within the Datasheet 200f. This document is your key to understanding and successfully implementing the component or system.